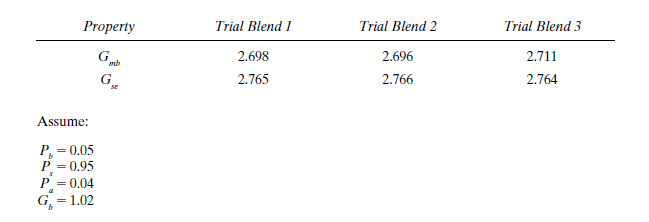

The initial trial asphalt content for different blends.

Answer to Problem 16P

Explanation of Solution

Given information:

Nominal maximum sieve of each aggregate blend = 19 mm.

Calculation:

For trial blend 1, we have:

The amount of asphalt binder absorbed by the aggregates is estimated

from Eq. 18.18 as

Where,

Substitute the values in the required equation, we have

Estimate the percent of effective asphalt binder by volume using theempirical expression given as follows:

Where,

gradation (mm).

Substitute the values in the required equation, we have

Now, calculate the mass of aggregate by using the following formula:

Where,

Substitute the values, we have

A trial percentage of asphalt binder then is determined for each trial

aggregate blend using the following equation.

Where,

Substitute the values, we have

For trial blend 2, we have:

The amount of asphalt binder absorbed by the aggregates is estimated

from Eq. 18.18 as

Where,

Substitute the values in the required equation, we have

Estimate the percent of effective asphalt binder by volume using the empirical expression given as follows:

Where,

gradation (mm).

Substitute the values in the required equation, we have

Now, calculate the mass of aggregate by using the following formula:

Where,

Substitute the values, we have

A trial percentage of asphalt binder then is determined for each trial

aggregate blend using the following equation.

Where,

Substitute the values, we have

For trial blend 3, we have:

The amount of asphalt binder absorbed by the aggregates is estimated

from Eq. 18.18 as

Where,

Substitute the values in the required equation, we have

Estimate the percent of effective asphalt binder by volume using the empirical expression given as follows:

Where,

gradation (mm).

Substitute the values in the required equation, we have

Now, calculate the mass of aggregate by using the following formula:

Where,

Substitute the values, we have

A trial percentage of asphalt binder then is determined for each trial

aggregate blend using the following equation.

Where,

Substitute the values, we have

Conclusion:

Therefore, the initial trial asphalt content for1st, 2nd and 3rd blends is as follows

Want to see more full solutions like this?

Chapter 18 Solutions

Traffic and Highway Engineering

- Table below shows the sieve analysis test result for aggregates A and B and the specification limits for an asphalt concrete. Determine the blend proportion required to meet the specification and the graduations of the blend. On a semi-log gradation graph, plot the gradations of aggregate A, aggregate B, the selected blend, and the specification limits in a same graph (you can use Excel sheets or you can draw the graphs on a semi-log attached to page 3 of this assignment). 19 12.5 9.5 4.75 2.36 0.60 0.30 0.15 Specification limit 100 80-100 70-90 50-70 35-50 18-29 13-23 8-16 Aggregate A 100 90 45 35 12 10 3 0 Aggregate B 100 100 100 80 77 45 32 18 Percentage passing % 0.001 0.01 0.1 1 10 100 Sieve Size (mm)arrow_forwardA sample of aggregate weighing of 3800g. 45.5% retaining on sieve No.4. and 48.5% it is retaining on sieve No 200. If bulk specific - gravities of coarse , fine and mineral filler aggregates are 2.59 , 2.66 , and 2.69 respectively, determine the optimum asphalt conten as a percentage of the total mix if results obtained using the Marshall method are shown in the table below. The specific gravity of the asphalt is 1.05. Given that the specifications required minimum Marshal Stability of ( 7kN ). Flow (2-4mm) and percent of air voids (3-5%). (Note: if the mix is not satisfy the requirement, please explain how to adjust it). Marsha test Weight of sample (gm) Asphalt content (%) Stability (kN) Flow (mm) In air In water 0.04 1260.4 716.3 6.25 2.9 0.045 1298.9 747.8 7.1 3.2 0.05 1127.7 652.9 7.9 3.8 0.055 1222.5 705.6 7.5 4.5 0.06 1182.6 679.8 5.9 6.05arrow_forwardBased on the data shown in Table P9.31, select the blend for a Superpave design aggregate structure. Assume <0.3 million ESAL and 19 mm nominal maximum aggregate size. TABLE P9.31 Blend Data 1 3 Gmb Gmm 2.451 2.465 2.467 2.585 2.654 2.584 Gp 1.030 1.030 1.030 P 5.9 5.5 5.8 94.1 94.5 94.2 Ра 4.5 4.5 4.5 Gşb 2.657 2.667 2.705 Hini 127 135 124 Håes 113 114 118arrow_forward

- Max specific gravity of mixture = 2.48 and following details are given. Bulk specific gravity aggregates in the mix and asphalt absorbed (%) are respectively, Material Specific gravity Mix Composition Asphalt Cement 1.02 6.40 Coarse Aggregate 2.51 52.35 Fine Aggregate 2.74 33.45 Mineral filler 2.69 7.80 2.603 and 3.10 2.538 and 2.60 2.603 and 2.08 2.538 and 3.20arrow_forwardAs part of mix design, a laboratory-compacted cylindrical asphalt specimen is weighed for determination of bulk-specific gravity. The following numbers are obtained:Dry mass in air = 1264.7 gramsMass when submerged in water = 723.9 gMass of saturated surface dry (SSD) = 1271.9 ga. What is the bulk-specific gravity of the compacted specimen (Gmb)?b. If the maximum theoretical specific gravity of the specimen (Gmm) is 2.531, what would be the air void content of the specimen in percent?arrow_forwardThoroughly mix the aggregate sample and reduce it to an amount suitable for testing, using a sample splitter or by quartering. The minimum sample size should be as follows: Minimum Mass, kg Fine aggregate with at least 95% passing 2.36-mm sieve 0.1 Fine aggregate with at least 85% passing 4.75-mm sieve 0.5 Coarse aggregate with a nominal maximum size of 9.5 mm 1 Coarse aggregate of a nominal maximum size of 12.5 mm 2 Coarse aggregate of a nominal maximum size of 19.0 mm Coarse aggregate of a nominal maximum size of 25.0 mm 10 Coarse aggregate of a nominal maximum size of 37.5 mm 15arrow_forward

- Based on the data shown in Table select the blend for a Superpave design aggregate structure. Assume 60.3 million ESAL and 19 mm nominal maximum aggregate size.arrow_forwardUse the following volumetric relationships for asphalt mix analysis: VTM = 100 (1 - Gmb) VFA = 100 3. An asphalt concrete specimen has the following properties: Asphalt content = 5.5 % by total weigh of mix Bulk specific gravity of the mix = 2.475 Theoretical maximum specific gravity = 2.563 Bulk specific gravity of aggregate = 2.689 Assuming there is no absorption of binder, calculate the following: (a) Percent Voids in Total Mix (b) Percent Voids in Mineral Aggregate: VMA – VTM VMA (c) Percent Voids filled with asphalt: VMA = = (100 - Gmb Ps Gsbarrow_forward3. As part of mix design, a laboratory-compacted cylindrical asphalt specimen is weighed for determination of bulk specific gravity. The following numbers are obtained: Dry Mass in air = 1264.7 grams • Mass when submerged in water = 723.9 grams • Mass of Saturated Surface Dry (SSD) = 1271.9 grams %3D a.What is the bulk specific gravity of the compacted specimen (Gmb)? b.lf the maximum theoretical specific gravity of the specimen (Gmm) is 2.531, what would be the air void content of the specimen in percent? c. If the bulk specific gravity of aggregates is 2.675 and asphalt content is 5.5%, what is the voids in mineral aggregate and voids filled with asphalt in percent? Ignore absorption.arrow_forward

- The mix design for an asphalt concrete mixture requires 2 to 6% minus No.200. The three aggregates shown in Table are available.Considering that approximately equal amounts of coarse and intermediateaggregate will be used in the mix, what is the percentage of fine aggregate that will give a resulting minus No. 200 in the mixture in the middle of the range,about 4%?arrow_forwardThe mix design for an asphalt concrete mixture requires 2 to 6% minus 0.075 mm. The three aggregates shown in Table P.5.34 are available. TABLE P5.34 Minus 0.075 mm Coarse 0.5% Intermediate 1.5% Fine Aggregate 11.5% Considering that approximately equal amounts of coarse and intermediate aggregate will be used in the mix, what is the percentage of fine aggregate that will give a resulting minus 0.075 mm in the mixture in the middle of the range, about 4%?arrow_forwardLaboratory specific gravity and absorption tests are run on two coarse aggregate sizes, which have to be blended. The results are as follows:Aggregate A: Bulk specific gravity = 2.491; absorption = 0.8,Aggregate B: Bulk specific gravity = 2.773; absorption = 4.6,a. What is the specific gravity of a mixture of 60% aggregate A and 40% aggregate B by weight?b. What is the absorption of the mixture?arrow_forward

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning